Gantry Cranes: Essential Tools in Modern Industry

Introduction to Gantry Cranes

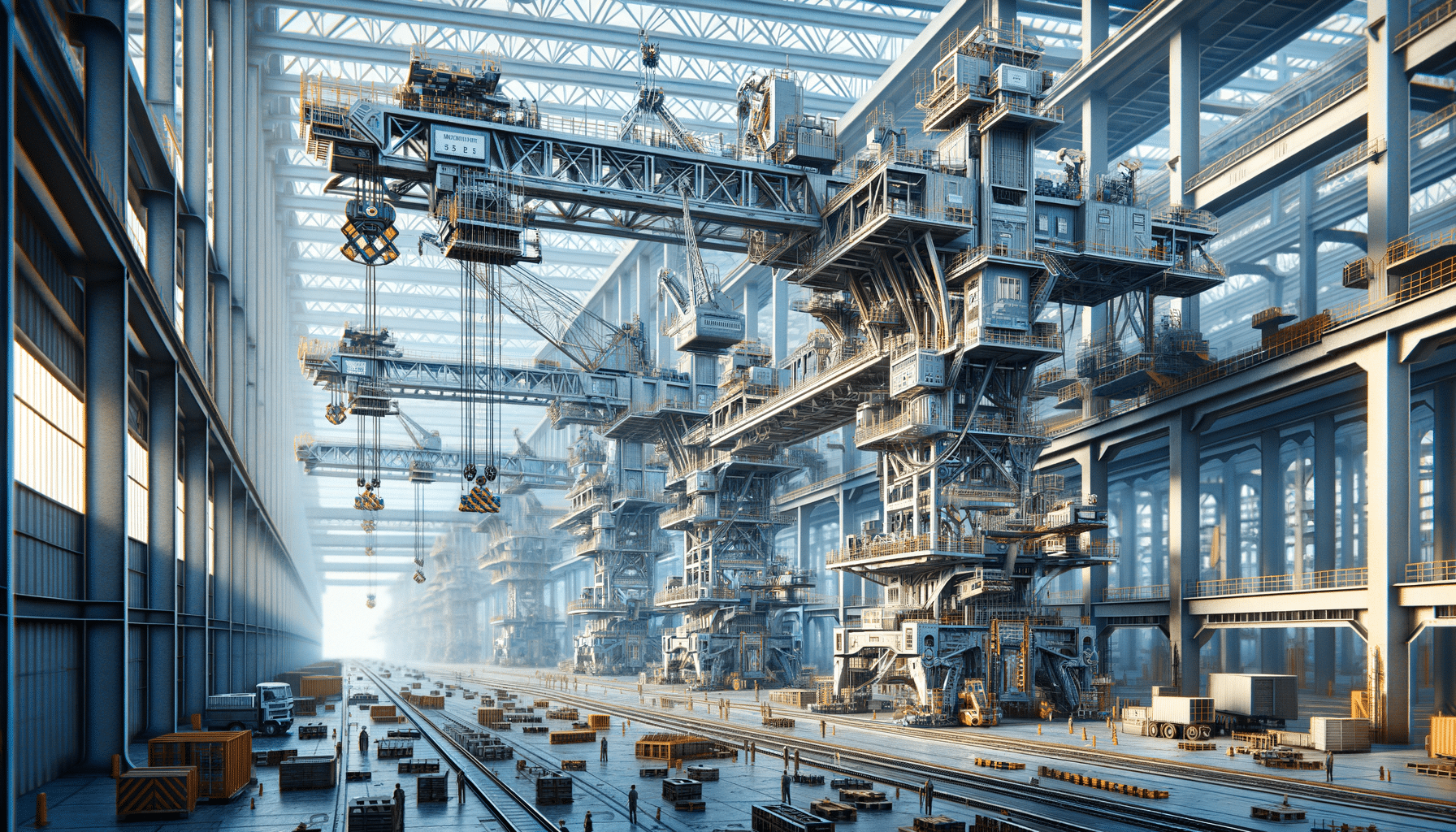

Gantry cranes are indispensable in the world of heavy lifting and material handling across various industries. These cranes, characterized by their unique structure and functionality, have become a staple in sectors ranging from construction to shipping. Their ability to lift and move heavy loads with precision and efficiency makes them a vital component in modern industry. Understanding the role and capabilities of gantry cranes can provide valuable insights into their importance and relevance in today’s industrial landscape.

Types and Configurations of Gantry Cranes

Gantry cranes come in various types and configurations, each designed to meet specific operational needs. The most common types include full gantry cranes, semi-gantry cranes, and portable gantry cranes. Full gantry cranes are typically used in large-scale industrial applications, offering robust support for heavy loads. Semi-gantry cranes, on the other hand, are ideal for environments where space is limited, as they require only one side to be supported by a leg. Portable gantry cranes provide flexibility and mobility, making them suitable for smaller operations or temporary projects.

Each configuration of gantry cranes can be further customized based on the operational requirements, such as load capacity, span, and lifting height. These variations allow industries to select the most appropriate type of crane for their specific needs, ensuring efficient and safe operations. The versatility of gantry cranes in terms of configurations and applications highlights their critical role in diverse industrial settings.

Applications of Gantry Cranes in Industry

The applications of gantry cranes are as diverse as the industries they serve. In the construction sector, these cranes are used for lifting and moving heavy materials such as steel beams and concrete blocks. Their ability to handle large loads with precision makes them invaluable in building infrastructure and large-scale projects.

In the shipping industry, gantry cranes are essential for loading and unloading cargo containers. Their towering structure and robust lifting capabilities make them perfect for handling the heavy and bulky containers used in global trade. Additionally, gantry cranes are utilized in manufacturing plants to transport materials and products across different stages of production, enhancing workflow efficiency.

The adaptability of gantry cranes to various industrial applications underscores their importance in facilitating operations that require heavy lifting and precise material handling.

Safety and Maintenance Considerations

Safety is a paramount concern when operating gantry cranes, given the heavy loads they handle. Proper training and adherence to safety protocols are essential to prevent accidents and ensure the well-being of operators and workers. Regular maintenance and inspections are crucial to identify potential issues and ensure the crane’s optimal performance.

Maintenance of gantry cranes involves checking the structural integrity, inspecting mechanical components, and ensuring that all safety devices are functioning correctly. Routine maintenance not only extends the lifespan of the crane but also minimizes the risk of unexpected breakdowns that can disrupt operations.

By prioritizing safety and maintenance, industries can maximize the efficiency and reliability of gantry cranes, ensuring they continue to play a vital role in material handling processes.

Future Trends and Innovations in Gantry Cranes

The future of gantry cranes is poised for exciting developments, driven by technological advancements and evolving industrial needs. Innovations such as automation and remote operation are set to enhance the efficiency and safety of gantry crane operations. Automation allows for precise control and reduces the need for manual intervention, while remote operation provides flexibility and enhances safety by allowing operators to control the crane from a safe distance.

Furthermore, the integration of smart technologies and IoT in gantry cranes is expected to improve monitoring and maintenance processes. Real-time data collection and analysis can provide insights into crane performance, enabling predictive maintenance and reducing downtime.

As industries continue to evolve, gantry cranes will adapt to meet new challenges and demands, ensuring they remain an essential tool in material handling and heavy lifting operations.