Guide to Choosing Affordable Laser Welding Machines

Introduction to Laser Welding Technology

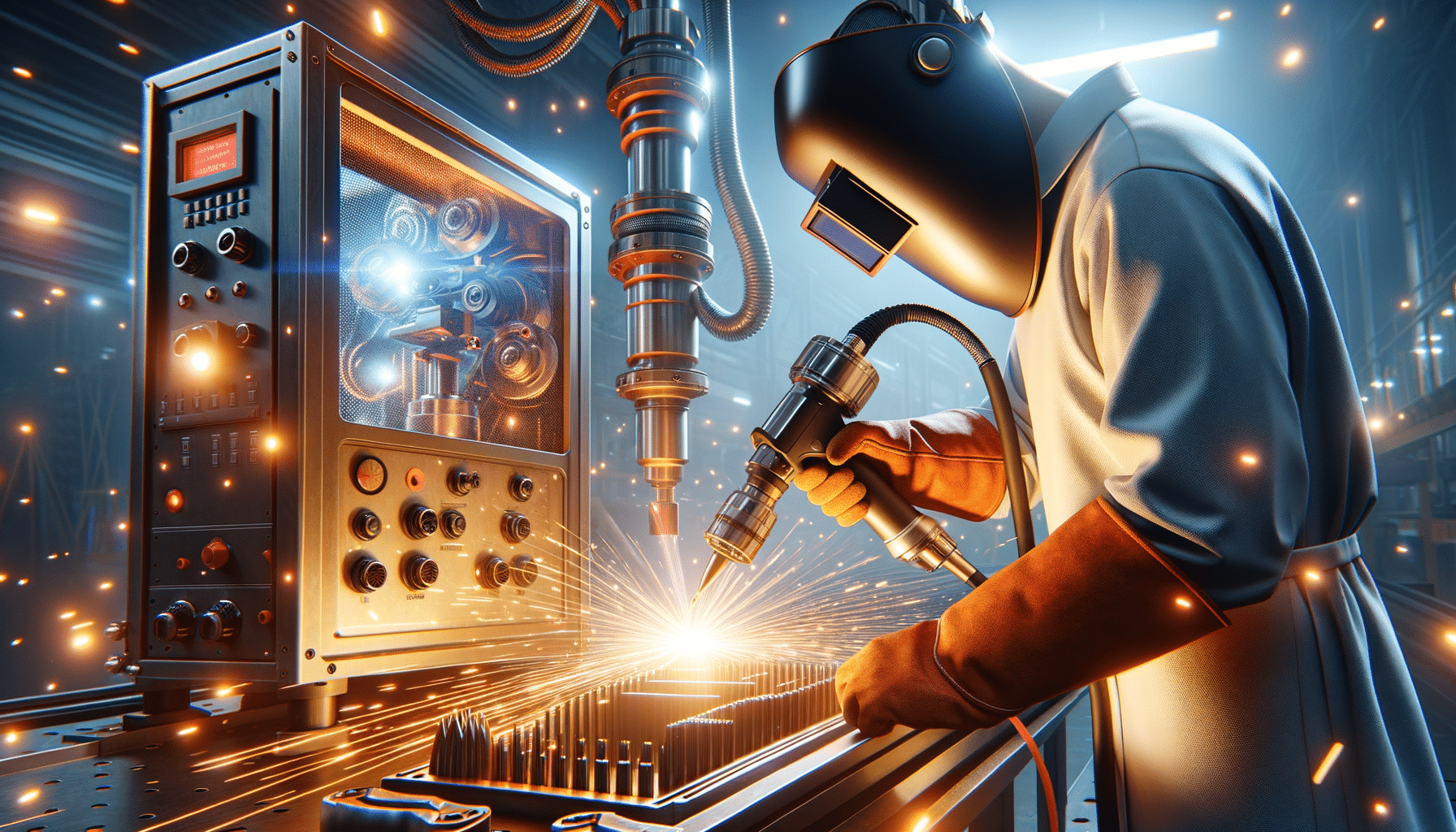

Laser welding technology has revolutionized the way industries approach metal joining processes. With precision and efficiency, laser welders are now a staple in sectors such as automotive, aerospace, medical device manufacturing, and jewelry making. The significance of laser welding machines lies in their ability to create strong, precise welds with minimal thermal distortion, making them ideal for delicate and complex applications.

Laser welding machines use a concentrated beam of light to melt and fuse materials together. This process is not only fast but also highly accurate, allowing for intricate designs and detailed work. The versatility of laser welding equipment makes it a valuable investment for businesses looking to improve their production capabilities while maintaining high-quality standards.

Types of Laser Welding Machines

When considering laser welding machines, it’s essential to understand the different types available on the market. Each type offers unique advantages, making them suitable for specific applications:

- Fiber Laser Welders: Known for their high efficiency and low maintenance, fiber laser welders are ideal for industrial applications. They offer excellent beam quality and are suitable for welding a variety of metals.

- CO2 Laser Welders: These machines are often used for non-metallic materials. They are versatile and can handle a range of thicknesses, making them popular in the automotive and aerospace industries.

- Diode Laser Welders: Diode lasers are compact and energy-efficient, making them suitable for applications requiring precision and speed. They are commonly used in the medical and electronics industries.

Choosing the right type of laser welding machine depends on the specific needs of your business, including the materials you work with and the precision required for your projects.

Key Features to Consider

When investing in laser welding equipment, several key features should be considered to ensure you select the right machine for your needs:

- Power Output: The power output of a laser welder determines its ability to handle different materials and thicknesses. Higher power outputs are suitable for thicker materials, while lower outputs are ideal for delicate work.

- Beam Quality: The quality of the laser beam affects the precision and finish of the weld. High-quality beams provide cleaner and more accurate welds.

- Control Systems: Advanced control systems allow for greater precision and ease of use. Look for machines with user-friendly interfaces and programmable settings.

- Cooling Systems: Efficient cooling systems prevent overheating and ensure the longevity of the machine. Consider machines with integrated cooling solutions.

By focusing on these features, you can ensure that your laser welding machine meets your production needs and enhances your operational efficiency.

Applications and Benefits of Laser Welding

Laser welding machines offer numerous benefits across various industries due to their precision and versatility. Here are some common applications and advantages:

- Automotive Industry: Laser welders are used to join car body parts and components, providing strong and reliable welds that withstand stress and wear.

- Aerospace Industry: The precision of laser welding is crucial for manufacturing lightweight and durable components for aircraft.

- Medical Devices: Laser welding is used to create intricate and sterile components for medical devices, ensuring safety and functionality.

- Jewelry Making: Jewelers use laser welders to repair and create detailed designs without damaging delicate materials.

The benefits of using laser welding machines include reduced production time, improved product quality, and the ability to work with a wide range of materials. These advantages make laser welding an attractive option for businesses seeking to enhance their manufacturing processes.

Conclusion: Investing in Laser Welding Technology

Investing in a laser welding machine can significantly enhance your business’s production capabilities. By understanding the different types of laser welders, key features to consider, and the wide range of applications, you can make an informed decision that aligns with your operational needs and budget.

Laser welding machines offer exceptional precision, speed, and versatility, making them a valuable addition to any manufacturing process. Whether you are in the automotive, aerospace, medical, or jewelry industry, the right laser welding equipment can provide you with a competitive edge and improve the quality of your products.