Lathe Machines: Precision Engineering for Superior Metal and Woodworking

Introduction to Lathe Machines

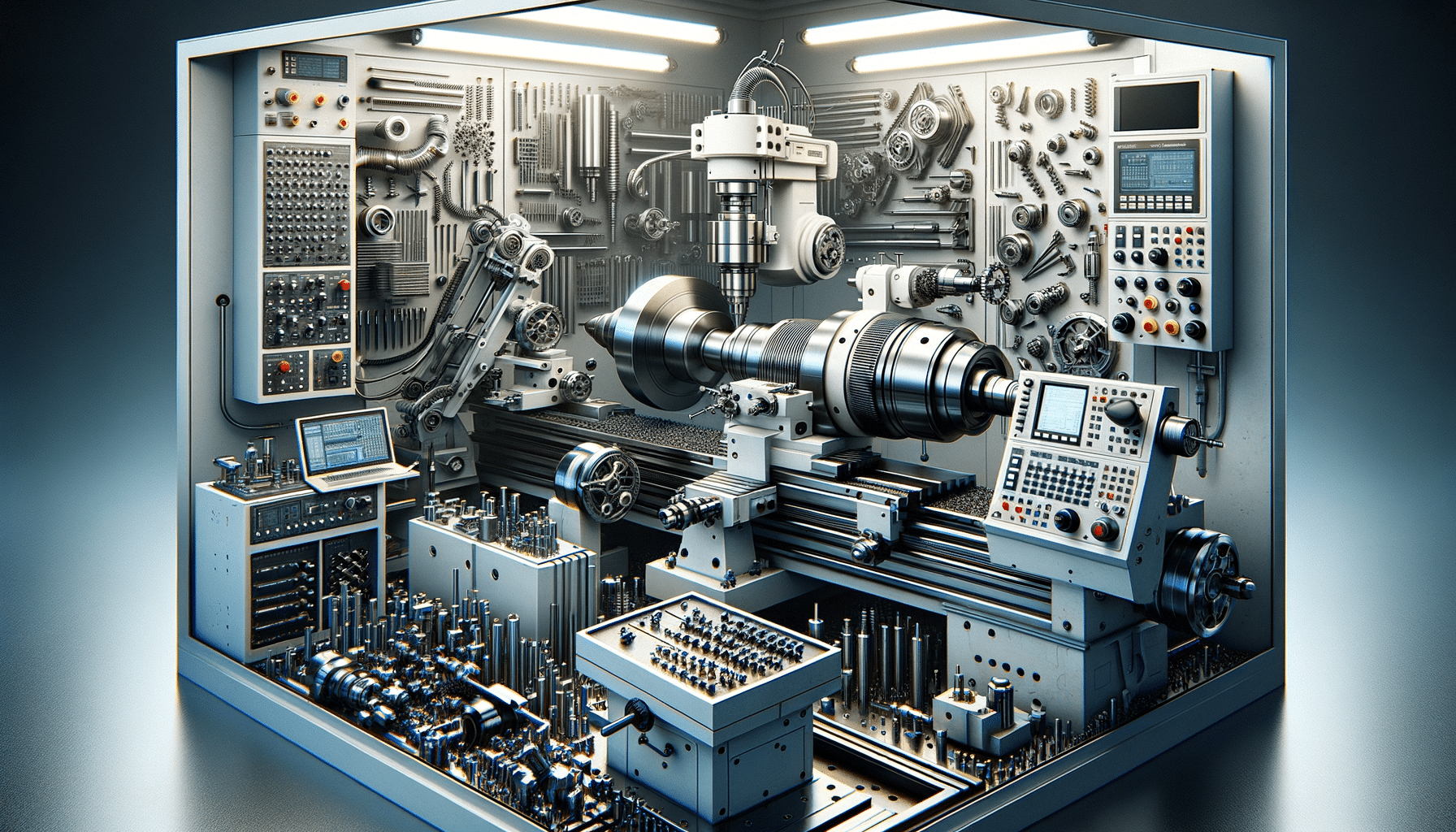

Lathe machines have been a cornerstone of manufacturing and craftsmanship for centuries. These versatile tools are essential for shaping and cutting materials, particularly metal and wood, with precision. Lathe machines operate by rotating the workpiece against a cutting tool, allowing for detailed and intricate designs. Their importance in industries ranging from automotive to aerospace cannot be overstated, as they enable the production of components with exceptional accuracy and consistency.

In today’s competitive manufacturing landscape, the demand for high-quality, durable, and precise lathe machines is ever-increasing. As technology advances, so do the capabilities of these machines, making them indispensable in both traditional and modern manufacturing settings.

The Evolution of Lathe Machines

Lathe machines have evolved significantly since their inception. Initially, they were manually operated, requiring skilled artisans to control the cutting tools with precision. Over time, technological advancements led to the development of powered lathes, which increased efficiency and accuracy.

The introduction of Computer Numerical Control (CNC) technology revolutionized the industry by automating the control of machine tools. CNC machines use pre-programmed software to dictate the movement of the cutting tools, allowing for complex and precise operations that were previously unattainable with manual machines.

Today, CNC lathe machines are widely used across various industries due to their ability to produce intricate designs with minimal human intervention. This evolution has not only improved productivity but has also expanded the possibilities of what can be achieved with lathe machines.

Understanding CNC Machines

CNC machines are a type of automated lathe that utilizes computer programming to control the movement of the cutting tools. This technology allows for high precision and repeatability, making it ideal for mass production and complex designs.

The key components of a CNC machine include the computer system, which processes the input data, and the mechanical components, which execute the programmed instructions. This integration of software and hardware enables CNC machines to perform a wide range of operations, from simple cuts to intricate engravings.

CNC machines are highly regarded for their efficiency, as they can operate continuously with minimal supervision. This capability not only reduces labor costs but also ensures consistent quality across all produced parts.

Benefits of CNC Lathe Machines

CNC lathe machines offer numerous advantages over traditional manual lathes. One of the most significant benefits is their precision. CNC machines can achieve tolerances that are difficult to replicate manually, ensuring each piece is identical and meets exact specifications.

Another advantage is the reduced need for skilled labor. While traditional lathes require experienced operators, CNC machines can be programmed to perform complex tasks with minimal human intervention. This automation not only increases productivity but also reduces the likelihood of errors.

Additionally, CNC lathe machines are capable of producing complex designs that would be challenging or impossible to achieve manually. This capability opens up new possibilities for innovation and creativity in manufacturing.

Conclusion: The Future of Lathe and CNC Machines

As technology continues to advance, the future of lathe and CNC machines looks promising. The integration of artificial intelligence and machine learning into CNC systems is expected to further enhance their capabilities, allowing for even greater precision and efficiency.

For industries that rely on precision engineering, the continued development of these machines will be crucial. They provide the tools necessary to produce high-quality components that meet the demanding standards of modern manufacturing.

In conclusion, lathe machines, particularly CNC lathes, are an essential part of the manufacturing landscape. Their ability to deliver precision, efficiency, and innovation makes them invaluable tools for industries worldwide, ensuring they remain at the forefront of technological advancements.