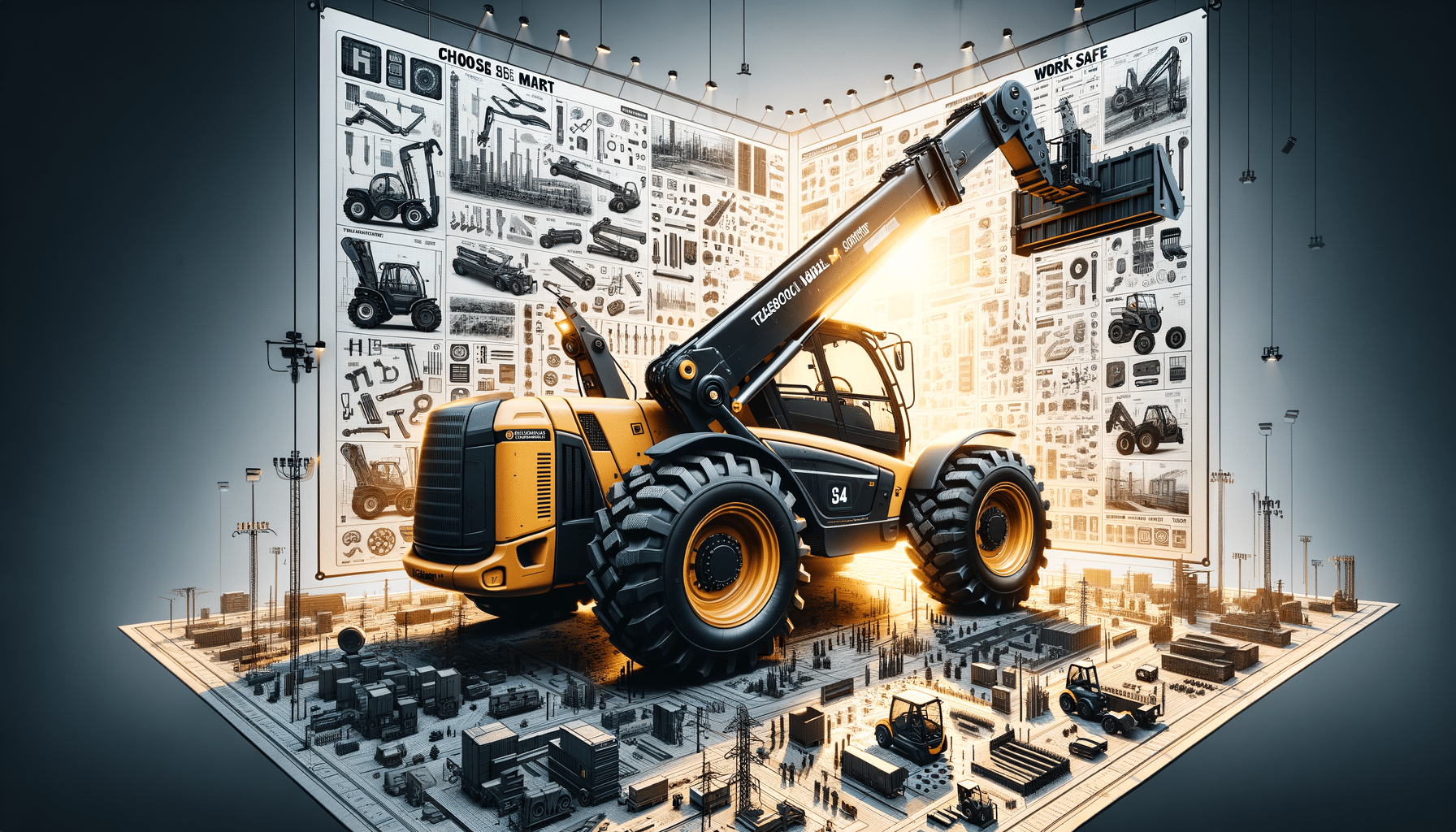

Choose Smart, Work Safe: Telescopic Telehandler

Telescopic handlers are versatile machines commonly used in construction, agriculture, and industrial applications. Here’s a comprehensive guide to help you select a reliable telehandler that meets your specific needs.

Introduction to Telescopic Telehandlers

In the realms of construction, agriculture, and industrial sectors, the telescopic telehandler emerges as a pivotal piece of machinery. Known for its versatility, this equipment combines the features of a forklift and a crane, offering an extended reach and lifting capability that is unmatched by many other machines. Whether you are lifting heavy loads to great heights or maneuvering in tight spaces, a telescopic telehandler can be a valuable asset. This guide delves into the various aspects of these machines, helping you make an informed choice tailored to your specific needs.

Understanding the Mechanics and Design

The design of a telescopic telehandler is engineered for both strength and flexibility. At its core, the telehandler features a telescopic boom that can extend forward and upward from the vehicle. This design allows it to reach places that traditional forklifts cannot. The boom can be fitted with various attachments such as buckets, winches, and pallet forks, enhancing its utility across different tasks.

Key components include:

- Telescopic Boom: Provides the machine with its extended reach, essential for accessing high or difficult-to-reach areas.

- Chassis: Built to support heavy loads and withstand the rigors of construction and industrial environments.

- Attachments: Versatile tools that can be swapped out depending on the task at hand, from lifting pallets to scooping materials.

The design considerations ensure that the telehandler remains stable even when the boom is fully extended, making it a safe choice for lifting operations.

Applications in Various Industries

Telescopic telehandlers are renowned for their adaptability across multiple industries. In construction, they are used for moving materials to elevated sites, such as scaffolding or rooftops. Their ability to handle heavy loads makes them indispensable for tasks that involve lifting and placing building materials.

In agriculture, these machines assist in handling bales of hay, feeding livestock, and even towing equipment. Their versatility allows farmers to perform a wide range of tasks without needing multiple machines. Industrial applications include loading and unloading goods in warehouses, where their ability to reach high shelves is particularly beneficial.

Overall, the telehandler’s multifunctionality makes it a valuable investment for any sector requiring heavy lifting and precise placement of materials.

Factors to Consider When Choosing a Telehandler

Selecting the right telescopic telehandler involves evaluating several critical factors. First, consider the load capacity you require. Telehandlers come in various sizes, each with a specific load limit. Ensuring that the machine can handle your typical load requirements is crucial.

Next, assess the reach and lift height needed for your operations. Different models offer varying boom extensions, impacting how high and far they can lift. Additionally, consider the terrain of your worksite. Some telehandlers are equipped with four-wheel drive and robust tires, making them suitable for rough or uneven surfaces.

Other factors include:

- Attachment Compatibility: Ensure that the telehandler can accommodate the attachments you plan to use.

- Operator Comfort: Features such as adjustable seats, intuitive controls, and good visibility can enhance productivity.

- Maintenance and Support: Availability of parts and service support can influence the overall cost of ownership.

By carefully evaluating these aspects, you can select a telehandler that aligns with your operational demands and budget.

Safety and Operational Guidelines

Operating a telescopic telehandler requires adherence to safety protocols to prevent accidents and ensure smooth operations. Training for operators is essential, as understanding the machine’s controls and capabilities can significantly reduce the risk of mishaps.

Key safety measures include:

- Regular Inspections: Conduct routine checks of the machine to identify any potential issues or wear that could compromise safety.

- Load Management: Always adhere to the load capacity limits and ensure that loads are balanced and secure before lifting.

- Stability Checks: Use stabilizers when necessary, especially when operating on uneven terrain or with the boom fully extended.

Incorporating these guidelines into daily operations not only enhances safety but also prolongs the lifespan of the equipment, ensuring it remains a reliable asset in your fleet.