Reliable Chain Trenchers: Efficiency Meets Durability

Introduction to Chain Trenchers

In the world of construction and landscaping, the need for precise and efficient trenching is paramount. Chain trenchers have emerged as a vital tool in this domain, offering an exceptional combination of power and precision. These machines are designed to cut through soil, rock, and other tough materials with ease, making them indispensable for a variety of projects. From laying utility lines to creating irrigation systems, chain trenchers ensure that the job is done efficiently and accurately. Their ability to handle different soil types and conditions makes them a versatile choice for contractors and landscapers alike.

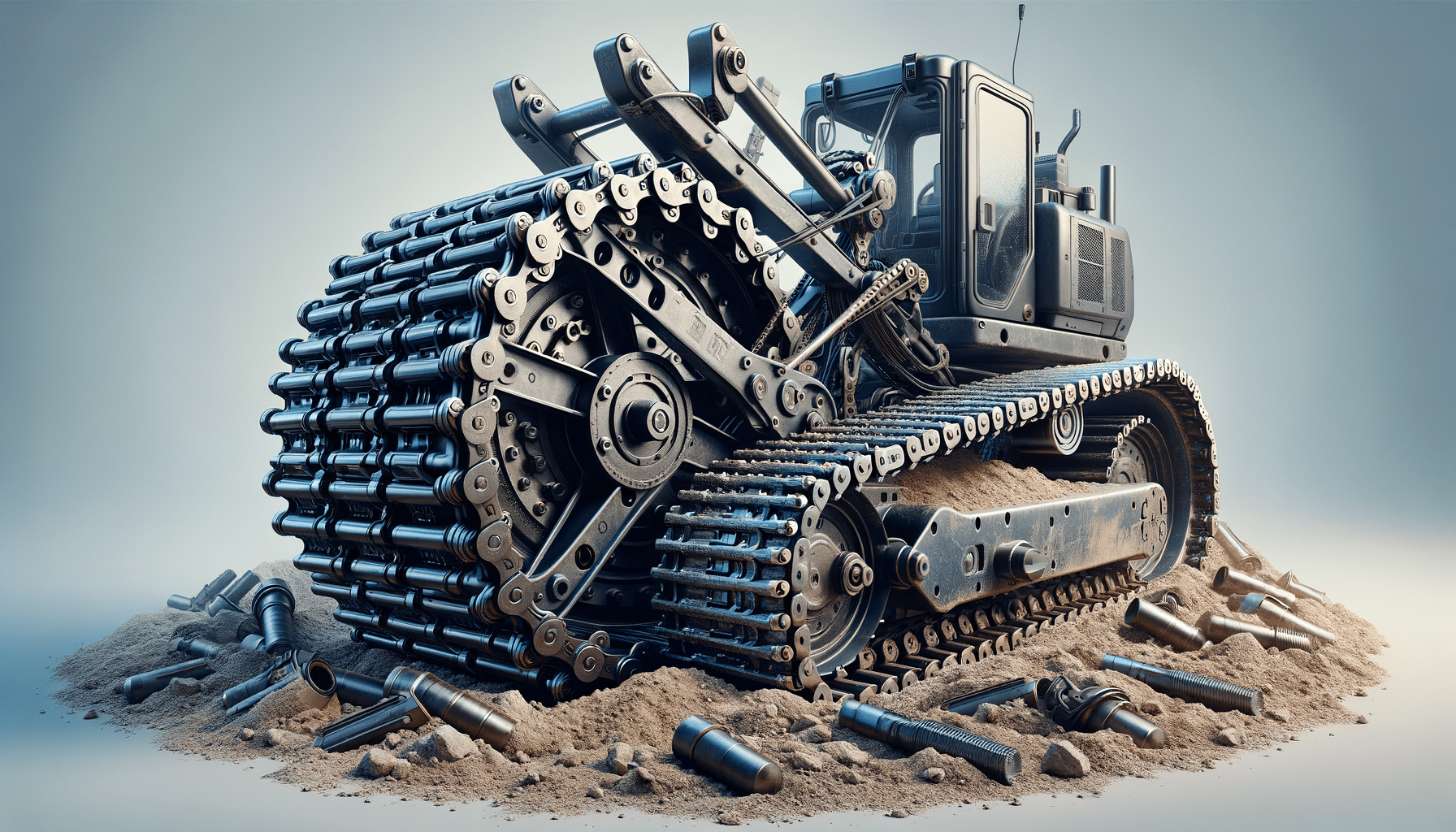

How Chain Trenchers Work

At the core of a chain trencher’s operation is its powerful digging chain, which is equipped with numerous cutting teeth. These teeth are designed to rotate around a boom, cutting into the ground to create a trench of the desired width and depth. The efficiency of a chain trencher lies in its ability to continuously remove soil and debris from the trench, allowing for uninterrupted progress. This mechanism is powered by a robust engine, which provides the necessary force to drive the chain through even the most challenging terrains. Additionally, operators can adjust the depth and width of the trench, offering flexibility to meet specific project requirements.

Applications of Chain Trenchers

Chain trenchers are employed in a wide range of applications, each requiring different specifications and capabilities. Some of the most common uses include:

- Installation of utility lines: Chain trenchers are ideal for creating narrow trenches for electrical, telecommunication, and water lines.

- Irrigation systems: They facilitate the laying of pipes and conduits for efficient water distribution in agricultural and landscaping projects.

- Road construction: These machines help in the construction of drainage systems and the installation of cables beneath road surfaces.

The versatility of chain trenchers makes them a preferred choice for contractors who need reliable and efficient equipment for various projects.

Advantages of Using Chain Trenchers

Chain trenchers offer several advantages that make them a popular choice among professionals. Some of these benefits include:

- Precision: The ability to adjust trench dimensions ensures precise excavation, reducing the risk of over-excavation.

- Efficiency: Continuous soil removal and high-speed operation significantly reduce project timelines.

- Durability: Built to withstand tough conditions, chain trenchers are designed for long-lasting performance.

These advantages contribute to the overall cost-effectiveness and reliability of chain trenchers, making them a valuable asset on any job site.

Choosing the Right Chain Trencher

Selecting the appropriate chain trencher for a project involves considering several factors. These include the type of soil, the required trench dimensions, and the specific application. It’s essential to evaluate the machine’s engine power, chain type, and cutting width to ensure it meets the demands of the task at hand. Additionally, operator comfort and ease of maintenance should be considered to enhance productivity and minimize downtime. By carefully assessing these elements, contractors can choose a chain trencher that delivers optimal performance and efficiency for their specific needs.