Understanding and Utilizing Concrete Tools: A Comprehensive Guide

Explore the essential concrete tools that enhance efficiency and precision in construction projects.

The Importance of Concrete Tools in Construction

Concrete tools are indispensable in the construction industry, playing a crucial role in ensuring the efficiency and quality of building projects. These tools are designed to handle the unique challenges posed by concrete, a material known for its durability and strength. The right set of tools can significantly impact the outcome of a project, influencing both the aesthetic and structural integrity of the construction.

Concrete tools facilitate various tasks such as mixing, pouring, finishing, and curing concrete. Each tool has a specific function, and their proper use can lead to smoother surfaces, stronger structures, and overall better results. For example, a concrete mixer ensures a homogeneous mix, which is essential for the strength and durability of the concrete. Similarly, trowels and floats are used to achieve a smooth finish on the surface.

In addition to enhancing the quality of work, concrete tools also contribute to safety on construction sites. By using the appropriate tools, workers can minimize the risk of accidents and injuries. This is particularly important when dealing with heavy materials like concrete, where mishandling can lead to serious consequences.

Types of Concrete Tools and Their Functions

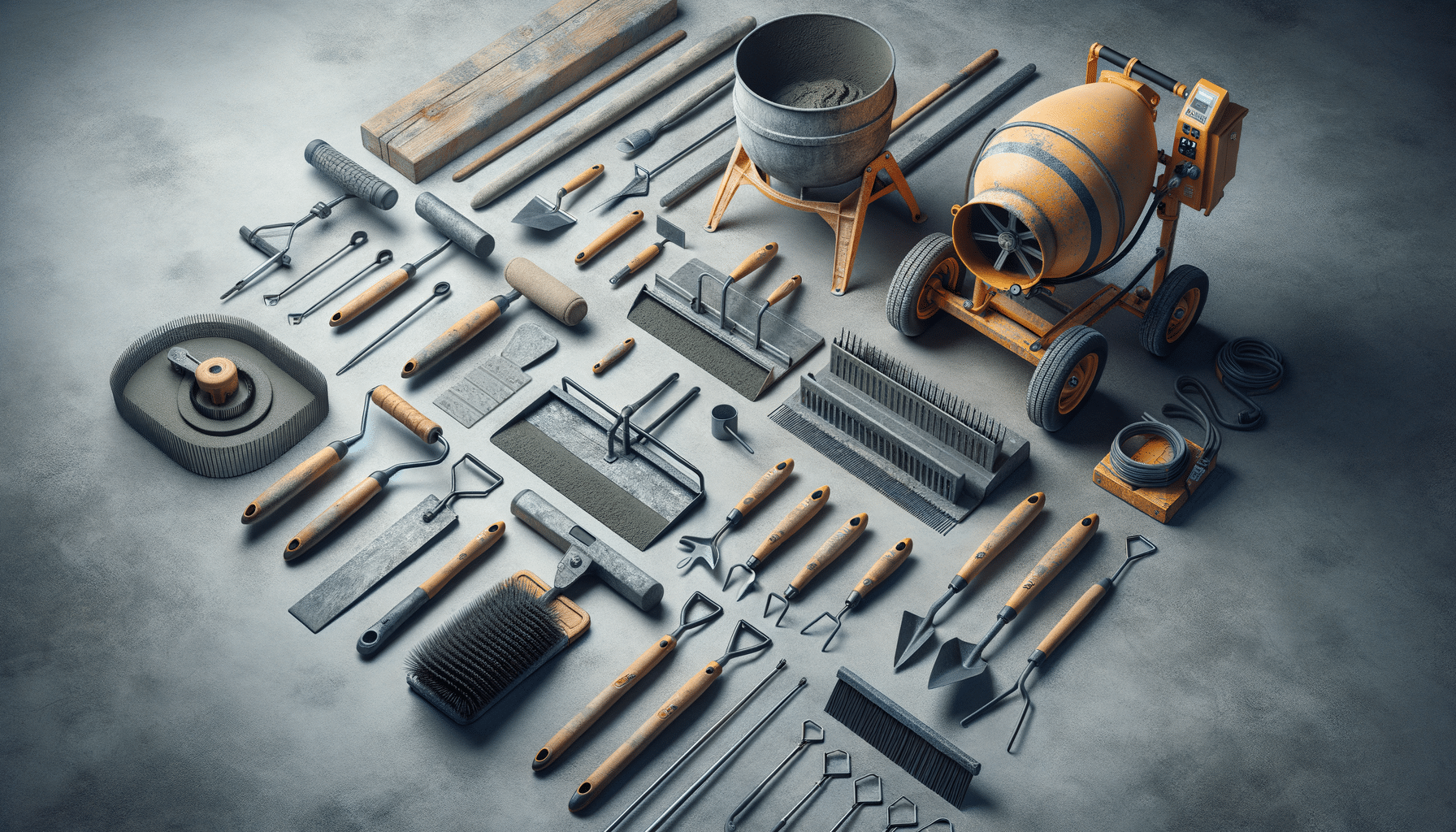

Concrete tools come in various forms, each designed for specific tasks. Understanding the different types of tools and their functions is essential for any construction professional. Here are some common concrete tools and their uses:

- Concrete Mixers: These machines are used to mix cement, aggregates, and water to create concrete. They ensure a consistent mix, which is crucial for the strength and durability of the concrete.

- Trowels: Trowels are used for smoothing and finishing concrete surfaces. They come in different sizes and shapes, each suited for specific tasks.

- Floats: Floats are used to level and smooth the surface of the concrete after it has been poured. They help remove any imperfections and prepare the surface for further finishing.

- Edgers: Edgers are used to create smooth, rounded edges on concrete slabs, preventing chipping and improving the overall appearance.

- Concrete Vibrators: These tools are used to remove air bubbles from the concrete mix, ensuring a dense and compact finish.

Each tool is essential in its own right, and using them correctly can make a significant difference in the quality and longevity of the construction project.

Choosing the Right Concrete Tools for Your Project

Selecting the appropriate concrete tools for a project depends on several factors, including the scale of the project, the specific tasks involved, and the desired finish. Here are some considerations to keep in mind when choosing concrete tools:

Firstly, assess the size and scope of the project. Larger projects may require heavy-duty tools such as large concrete mixers or industrial-grade vibrators. Smaller projects, on the other hand, might only need basic tools like hand trowels and small mixers.

Secondly, consider the specific tasks that need to be accomplished. For instance, if the project involves creating decorative concrete surfaces, specialized tools like stamps or stencils may be necessary. These tools allow for intricate patterns and textures, adding aesthetic value to the finished product.

Lastly, evaluate the desired finish of the concrete. Different tools can achieve various textures and finishes, from smooth and polished surfaces to rough and textured ones. The choice of tools will depend on the functional and aesthetic requirements of the project.

By carefully considering these factors, construction professionals can ensure they have the right tools for the job, leading to successful and efficient project completion.

Maintenance and Care of Concrete Tools

Proper maintenance and care of concrete tools are essential to ensure their longevity and performance. Given the demanding nature of construction work, these tools are often exposed to harsh conditions, which can lead to wear and tear. Here are some tips for maintaining concrete tools:

Regular cleaning is crucial. After each use, tools should be thoroughly cleaned to remove any concrete residue. Concrete left on tools can harden and become difficult to remove, potentially damaging the tool. Using water and a stiff brush can help in cleaning off the residue effectively.

Inspect tools regularly for any signs of damage or wear. Parts such as blades or handles may need replacement over time. Addressing these issues promptly can prevent further damage and ensure the tool remains functional.

Proper storage is also important. Tools should be stored in a dry environment to prevent rust and corrosion. Keeping them organized and in good condition will make them readily available for use when needed.

By following these maintenance practices, construction professionals can extend the lifespan of their concrete tools, ensuring they continue to perform effectively over time.

Innovations in Concrete Tools and Technology

The construction industry is continually evolving, and innovations in concrete tools and technology are at the forefront of this change. Modern advancements have led to the development of more efficient and precise tools, improving the overall quality and speed of construction projects.

One significant innovation is the introduction of battery-powered concrete tools. These tools offer greater mobility and convenience on construction sites, eliminating the need for cords and power outlets. They are particularly useful in remote locations where access to electricity may be limited.

Another advancement is the use of laser-guided tools for precision work. Laser levels and distance measurers allow for accurate alignment and measurement, reducing errors and enhancing the quality of the finished product.

Additionally, smart technology is making its way into concrete tools. Tools equipped with sensors and connectivity features can provide real-time data on performance and usage, helping professionals make informed decisions and optimize their work processes.

These innovations are transforming the way concrete work is done, making it more efficient, precise, and adaptable to the demands of modern construction projects.