The Pets Care Blog

Understanding Press Brake Machines: A Comprehensive Guide

Introduction to Press Brake Machines

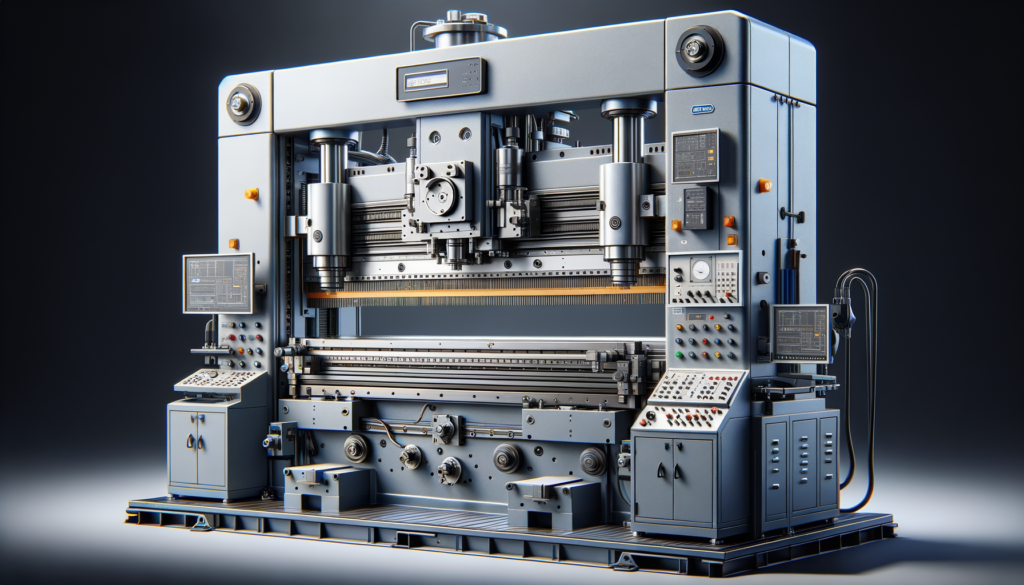

Press brake machines are pivotal in the realm of metalworking, serving as essential tools for bending and shaping sheet metal. These machines are renowned for their precision and versatility, making them indispensable in industries ranging from automotive to aerospace. Understanding the intricacies of press brake machines can provide valuable insights into their operation and application, enhancing productivity and efficiency in manufacturing processes.

Press brake machines are designed to bend sheet metal by clamping it between a matching punch and die. The machine applies force to the punch, which in turn bends the metal to the desired angle. The precision of this process is crucial, as even minor deviations can lead to significant discrepancies in the final product. This precision is achieved through advanced technology and meticulous engineering, ensuring that press brake machines deliver consistent and reliable results.

The Mechanics of a Press Brake

At the heart of a press brake machine is its mechanical system, which is responsible for applying the necessary force to bend the metal. This system can be powered in various ways, with hydraulic, mechanical, and pneumatic systems being the most common. Each system has its unique advantages and is suited to different applications, allowing manufacturers to choose the one that best fits their needs.

Hydraulic press brakes are particularly popular due to their ability to apply a consistent force throughout the bending process. This consistency is achieved through the use of hydraulic fluid, which transmits force to the punch and die. The hydraulic system allows for precise control over the bending process, making it ideal for applications that require high levels of accuracy. Additionally, hydraulic press brakes are known for their durability and ability to handle large volumes of work, making them a preferred choice in many industrial settings.

Exploring Hydraulic Press Brakes

Hydraulic press brakes represent a significant advancement in metalworking technology, offering unparalleled precision and control. These machines utilize hydraulic fluid to generate the force needed to bend metal, allowing for smooth and accurate operation. The hydraulic system is composed of a pump, valves, and cylinders, which work in unison to deliver the required force to the punch and die.

One of the key advantages of hydraulic press brakes is their ability to handle a wide range of materials and thicknesses. This versatility makes them suitable for various applications, from simple bends to complex shapes. Moreover, hydraulic press brakes are equipped with advanced features such as programmable controls and automated back gauges, which enhance their functionality and ease of use. These features allow operators to achieve precise bends with minimal effort, reducing the likelihood of errors and improving overall efficiency.

Applications and Benefits of Press Brake Machines

Press brake machines are used in a myriad of applications, each benefiting from the machine’s ability to produce precise and consistent bends. In the automotive industry, for example, press brakes are used to create components such as brackets and frames, which require exact specifications to ensure proper fit and function. Similarly, in the aerospace sector, press brakes are employed to fabricate parts that must withstand extreme conditions and stresses.

The benefits of using press brake machines extend beyond their precision and versatility. These machines also contribute to improved productivity and reduced waste, as they enable manufacturers to produce high-quality parts with minimal material loss. Additionally, the automation capabilities of modern press brakes reduce the need for manual intervention, allowing operators to focus on other critical tasks and further enhancing efficiency.

- Increased precision and accuracy

- Versatility in handling different materials

- Enhanced productivity and efficiency

- Reduced material waste

- Automation capabilities for streamlined operations

Conclusion: The Future of Press Brake Technology

As technology continues to evolve, so too does the potential of press brake machines. The integration of digital controls and automation is transforming the way these machines operate, offering new levels of precision and efficiency. This evolution is paving the way for more complex and intricate designs, expanding the possibilities for manufacturers across various industries.

Looking ahead, the future of press brake technology promises to be exciting and transformative. With continued advancements in materials science and engineering, press brake machines will likely become even more versatile and capable, meeting the demands of an ever-changing manufacturing landscape. For businesses seeking to stay competitive, investing in modern press brake technology is a strategic move that can yield significant benefits in terms of quality, productivity, and cost-effectiveness.