Upgrade the Workshop with an Affordable Laser Welding Machine.

Introduction to Laser Welding

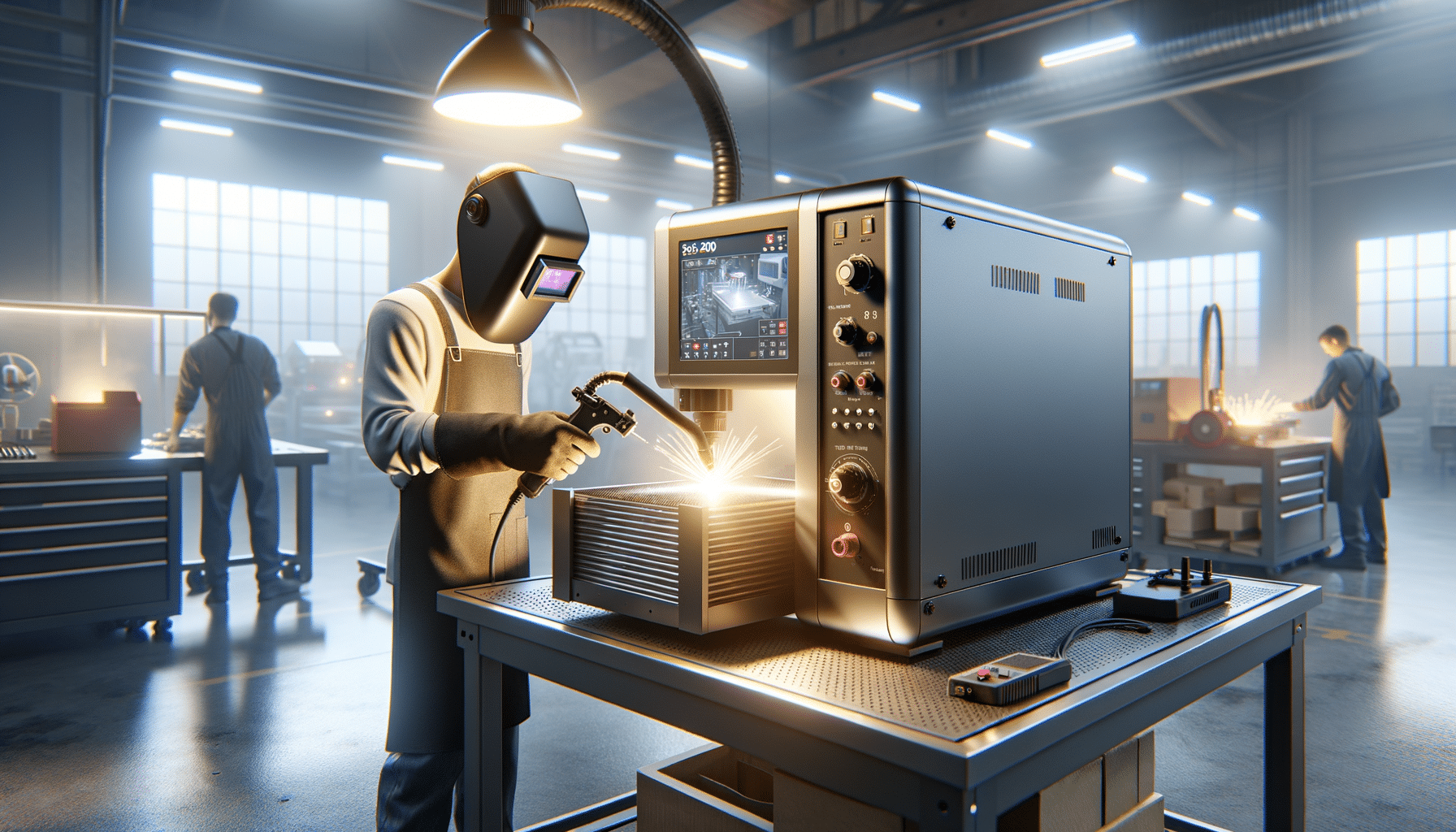

In the world of manufacturing and metalworking, precision and efficiency are key. Laser welding has emerged as a technological advancement that addresses these needs effectively. This process utilizes a concentrated beam of light to join materials, typically metals or thermoplastics, with high precision. The significance of laser welding lies in its ability to produce strong, clean welds with minimal distortion, making it a preferred choice in various industries, including automotive, aerospace, and electronics.

Laser welding offers several advantages over traditional welding methods. It is known for its speed and precision, which significantly reduces the time and cost associated with manual welding techniques. Moreover, the ability to control the laser beam with high accuracy allows for intricate and delicate work, which is particularly beneficial in industries where precision is paramount.

Understanding Laser Welding Machines

Laser welding machines are at the heart of this innovative process. These machines are designed to deliver a focused laser beam to the workpiece, creating a weld that is both precise and strong. The technology behind these machines is sophisticated, involving components such as laser sources, delivery systems, and control units. Despite their complexity, modern laser welding machines are user-friendly and can be integrated into various production lines with ease.

One of the key benefits of laser welding machines is their versatility. They can be used on a wide range of materials, including stainless steel, aluminum, and even certain plastics. This adaptability makes them a valuable asset in diverse manufacturing environments. Additionally, laser welding machines offer the advantage of non-contact processing, which means there is less wear and tear on the equipment, leading to longer machine life and reduced maintenance costs.

- High precision and control

- Reduced material distortion

- Lower operational costs

Benefits of Laser Welding Machines

The benefits of using laser welding machines extend beyond just precision and speed. One significant advantage is the quality of the welds produced. Laser welds are typically cleaner and stronger, with minimal porosity and defects. This results in a superior finish that requires little to no post-processing, saving both time and resources.

Another benefit is the ability to automate the welding process. Laser welding machines can be easily integrated with robotic systems, allowing for automated welding in high-volume production settings. This not only increases productivity but also ensures consistent quality across all welds. Furthermore, the use of laser welding can lead to significant energy savings, as the process is highly efficient and requires less energy compared to traditional welding methods.

- Improved weld quality

- Automation capabilities

- Energy efficiency

Why Choose Laser Welders?

Choosing laser welders over traditional welding methods can be a game-changer for many businesses. The decision to invest in laser welding technology is often driven by the need for greater efficiency, precision, and quality in production processes. Laser welders are particularly advantageous for industries that require high levels of accuracy and minimal material distortion.

Moreover, laser welders offer a cleaner work environment. Since the process is non-contact and generates minimal fumes and spatter, it reduces the need for extensive cleanup and improves workplace safety. Additionally, the ability to perform complex welds with ease makes laser welders a preferred choice for manufacturers looking to innovate and stay competitive in their fields.

- Enhanced efficiency and productivity

- Cleaner and safer work environment

- Capability to handle complex tasks

Conclusion: Embracing Laser Welding Technology

In conclusion, laser welding machines present a compelling case for businesses aiming to improve their manufacturing processes. The combination of precision, speed, and versatility makes laser welding a valuable tool in modern production environments. By adopting laser welding technology, companies can achieve higher quality products while reducing costs and increasing efficiency.

As industries continue to evolve and demand more innovative solutions, laser welding stands out as a technology that meets these challenges head-on. Whether it’s for enhancing productivity or ensuring superior product quality, laser welding machines are an investment that promises significant returns.